|

Aerial Acoustics

Accuratezza

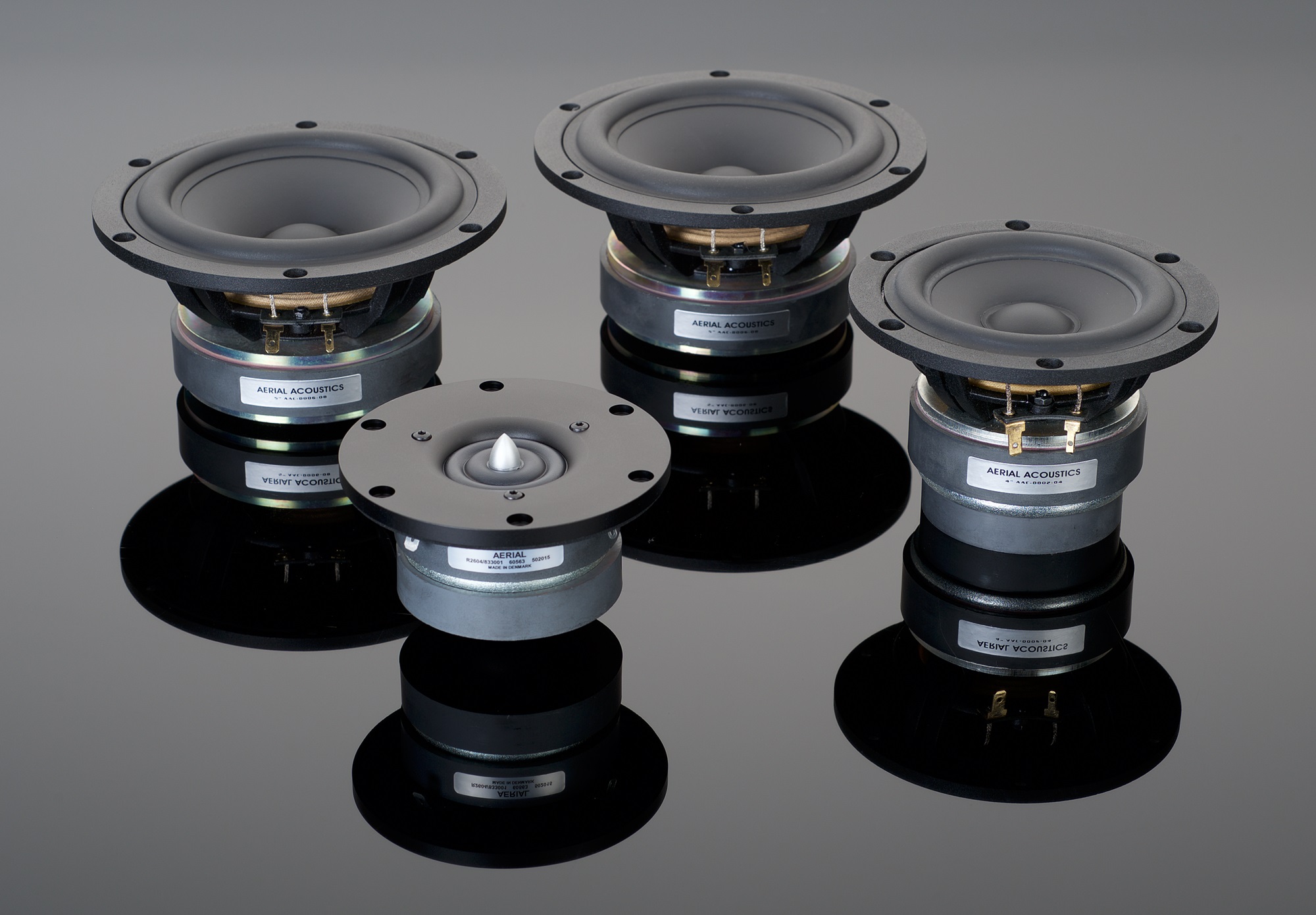

Drivers estremamente rigidi e leggeri uniti all’utilizzo di magneti generosi permettono la ricreazione di timbriche sorprendentemente reali.

Precisione

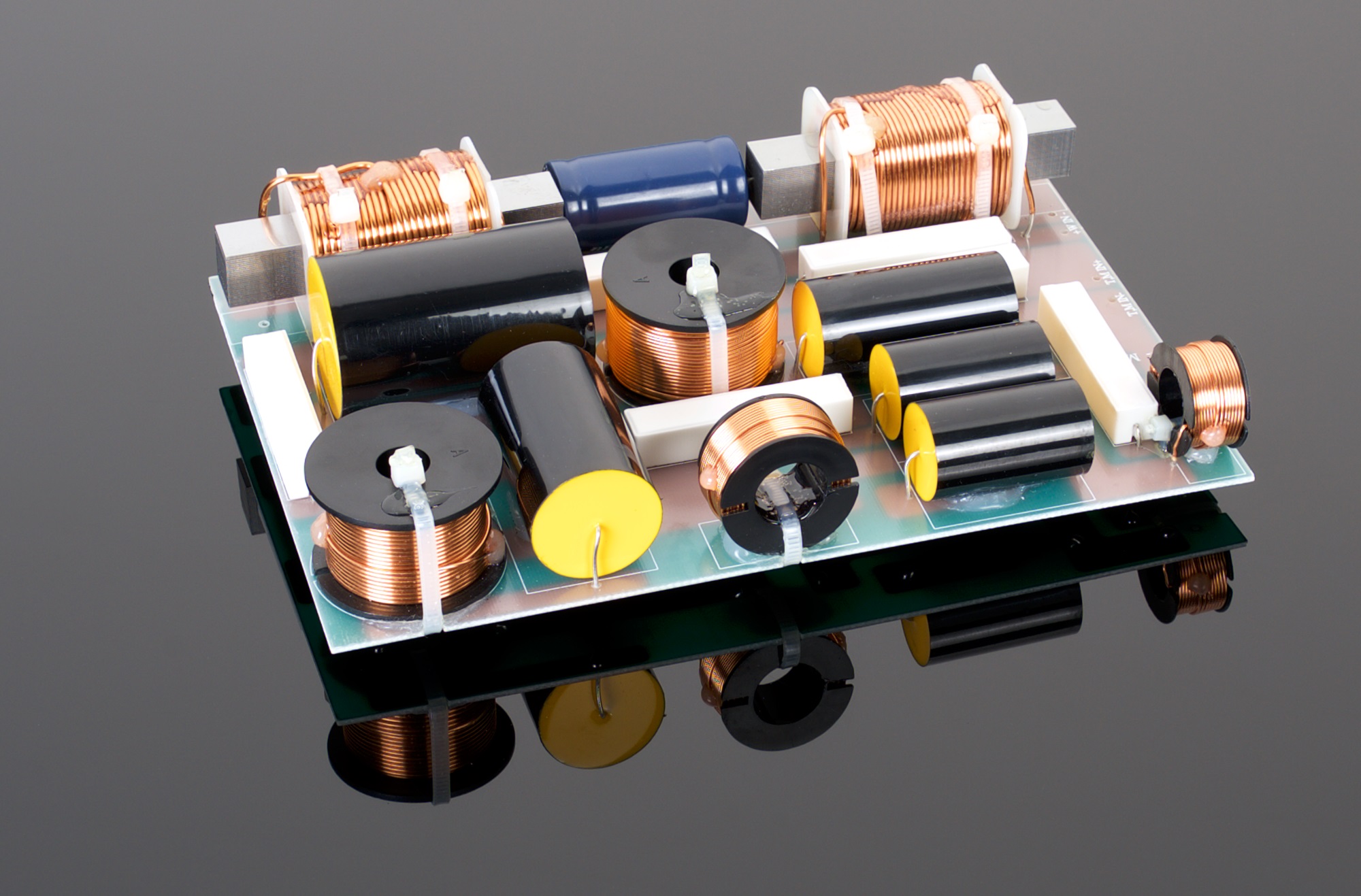

I crossover sono progettati per permettere a ciascun driver riprodurre il range di frequenze a cui è destinato.

La trasparenza e la precisione che si percepiscono hanno come origine la totale assenza di distorsioni, dovute appunto alla mancanza di sovrapposizioni di ciascun elemento.

Qualità della costruzione

Costruire un prodotto che genera vibrazioni in uno spazio che non dovrebbe vibrare è realmente una sfida. Aerial unisce anni di tecnologia e studi sui materiali e le tecniche costruttive per realizzare un cabinet inerte, esteticamente attraente ed acusticamente efficace.

Michael Kelly e David Marshall sono due nomi piuttosto noti negli Stati Uniti perché dal 1989, anno in cui fondarono Aerial Acoustics, si sono distinti per l'originalità dei progetti e per i sorprendenti risultati che il loro lavoro ha prodotto. Michael Kelly e David Marshall sono due nomi piuttosto noti negli Stati Uniti perché dal 1989, anno in cui fondarono Aerial Acoustics, si sono distinti per l'originalità dei progetti e per i sorprendenti risultati che il loro lavoro ha prodotto.

Fin dai primi prototipi i progettisti hanno utilizzato tutta la loro capacità innovativa, progettando drivers proprietari o modificando drivers esistenti ed utilizzando materiali proprietari (Novalith).

Marshall si dedicò in particolar modo alla realizzazione di un crossover a fase accurata con pendenze di 24dB per ottava, quindi particolarmente efficace nell'assegnare specifiche bande di frequenza a ciascun driver del diffusore, evitando sovrapposizioni e relative distorsioni.

Il fine ultimo è stata la creazione di un diffusore, totalmente made in USA, che soddisfacesse l'orecchio particolarmente raffinato dei progettisti.

Il risultato fu raggiunto nel 1996 con la presentazione del modello 10T che divenne "Speaker of the Year" per Stereophile lo stesso anno.

Seguirono negli anni il modello 20T, "Speaker of the Year" per l'anno 2004 e restata Classe A e Stereophile Recommended Component fino al 2013 (anno del ritiro dalla produzione).

Ultime nate sono il modello 5T, 6T e 7T nominata anch'essa Classe A e Stereophile Recommended Component dal 2012 al 2015.

Torna all'inizio

Cabinet

A loudspeaker cabinet must provide the right air volume for the drivers while not affecting in even the smallest way the pure sound from the drivers. Ideally the cabinet should disappear sonically.

The Aerial Acoustics Model 7T is a good example. It uses 9 layers of 3 mm thin MDF impregnated with wet glue, then forced into a geometrically strong curved shape under 20 tons of pressure and held for 48 hours until the glue is hard. This construction traps the strong bending forces in the curved wood panel, stiffening them and improving their physical properties. Beyond this, the hardened glue saturating the thin laminations makes a wood/glue sandwich that is very hard and inert.

In addition extensive interlocking bracing runs side-to-side, front-to-back and top-to-bottom to naturally cancel the opposing vibrations from opposite walls. Separate front baffles are attached to the front of the cabinet with a soft damping glue to interrupt the energy flow from the drivers to the cabinet walls while increasing the mass of the front walls, further reducing even the smallest sounds from the cabinet. New Zealand long-fiber natural wool insulation is used in critical areas because of its superior sound quality.

German Danzer veneers are used on the wood finished cabinets. 10 layers of hard, high-density polyester are applied with hand-polishing between each layer. The painted finishes utilize high quality automotive paints. The gracefully curved grilles are acoustically open and mounted securely using 8 pairs of strong hidden Neodymium magnets.

Drivers

A loudspeaker systems drivers are the origin of the sound. They determine the upper limit to the sound quality of a speaker. Their sound quality must be as natural, detailed and perfect as possible without any unnatural artifacts. A loudspeaker systems drivers are the origin of the sound. They determine the upper limit to the sound quality of a speaker. Their sound quality must be as natural, detailed and perfect as possible without any unnatural artifacts.

Aerial Acoustics uses custom-designed proprietary drivers built specifically for Aerial primarily in Denmark. All acoustic parameters including magnets, voice coils, cone materials, glues and other materials are fully optimized for application in each Aerial speaker model to provide linear performance beyond their range of use. Drivers designed this way increase the maximum sound quality possible from a system.

One example is the larger magnet and coil structures used in Aerial drivers. We use longer coils allow than iss normal. This is to insure that the voicing of the speaker will not change when the playing volume is increased. It also extends dynamics without compression and lowers distortion. However this requires that larger magnet systems be used to maintain sensitivity. Voice coil formers are either titanium or glass fiber. All Aerial custom woofers are designed this way.

Crossover

The function of a crossover is to seamlessly blend the individual drivers to produce sound that is natural, delicate, dynamic, transparent and seems to come from a single driver. The function of a crossover is to seamlessly blend the individual drivers to produce sound that is natural, delicate, dynamic, transparent and seems to come from a single driver.

Aerial uses high quality metalized film capacitors and air core coils throughout the midrange and treble sections, while larger bass coils use low hysteresis nickel-steel laminations. Silver solder and Teflon insulated 99.99% high purity copper wiring is used. Crossover slopes are true acoustic 24 dB/oct.

Assembly, Testing, Listening

Since its beginnings in 1989, Aerial Acoustics has been offering high performance and quality, long-term listenability, and excellent value in high-end loudspeakers. By taking advantage of advances in materials, construction techniques, and acoustic analysis, Aerial has continued to improve its products over the years. This steady improvement has resulted in the current line, Aerial’s finest expression to date of design, finish, and sonic fidelity.

All Aerial Acoustics loudspeakers are designed, engineered and assembled in Massachusetts, USA.

Torna all'inizio

|

Sito web: http://www.aerialacoustics.com/

Sito web: http://www.aerialacoustics.com/  Sito web: http://www.aerialacoustics.com/

Sito web: http://www.aerialacoustics.com/